The next generation of energy-efficient windows.

Electrochromic windows automatically adjust to bring in natural light while controlling heat gain and glare. By using electricity to adjust the tint level of the glass, Miru eWindows can reduce air-conditioning loads, saving major energy and helping reduce GHGs.

A compelling, competitive advantage

- Extends EV range

- Dimmable

- Panoramic roofs

- Side lites

- Mirrors

- Neutral color

- High clarity

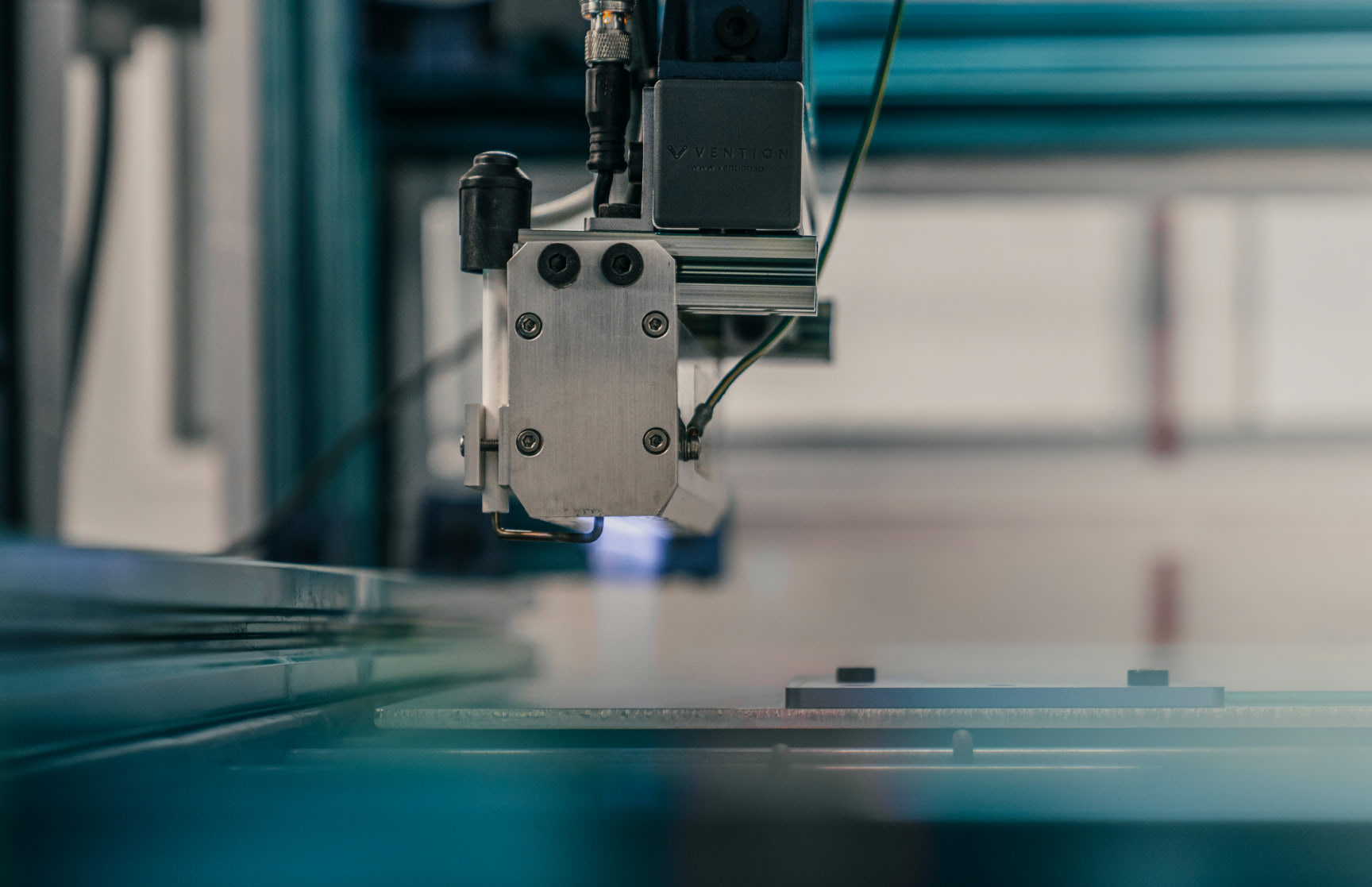

- Low cost of production

- Low DC power

- Low shock hazard